Technology innovations in the automotive industry are increasing in direction to reduce EV costs and make electric motors therefore electric vehicles even more attractive for consumers. Strict emission standards are implemented with a goal to combat various environmental problems. Automotive electrification is experiencing a significant increase since this technology addresses some of the environmental issues.

During electric motors and electric vehicles development, electric drive occupies an important position. Electric vehicle motor drives usually require frequent start/stop, high rate of acceleration/deceleration, high torque capability at low speed for hill climb performance. EV motor drives demand both high power density and high efficiency for the reduction of total vehicle weight and extension of driving range. Moreover, EV motor drives desire high controllability, high steady-state accuracy and good transient performance. Low acoustic noise and low torque ripple are also important design considerations. This article will address some of the possible technological guidelines for manufacturing of electric motors in terms of design, power density, materials and efficiency.

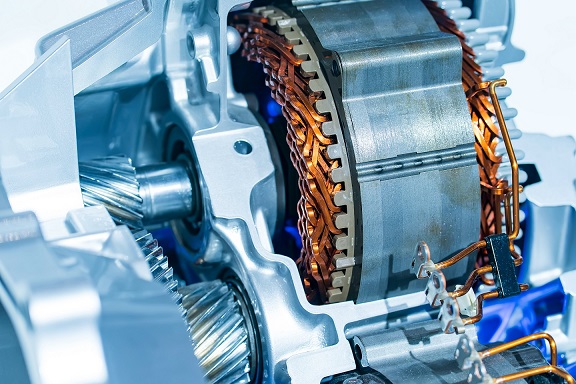

For the design of high power density electric motor the crucial factors affecting motor performance should be found from the electrical machine basic design. The electric motor is a strongly coupled nonlinear system, and its performance is affected by factors such as the phase number, slot/pole combination, and the rotor structure. According to the below equation, increasing the motor speed, phase number, winding coefficient, and pure copper area in the slot is beneficial to increasing the machine power density.

where ρe is motor power density in kW/kg, m is phase number, N is the number of conductors in the slot, and Is is the stator phase current RMS value in A. There are various motor topologies

that have been developed to achieve high power density, and a brief analysis of most used and new emerging technologies will be described.

Materials as a technological guideline for further development of electrical machines and electric motors for electric vehicles

In general, electric motors and machines for electric vehicles are made up of two different materials such as active and inactive materials. The active material depends on different motor topologies but usually consists of the magnetic core, winding and PMs, where the insulation, shaft, frame, and fan are inactive materials. Despite the fast development, the basic construction materials of an electric motor remain as it is for a longer period of time. However, advancements in technology help to invent various materials with improved properties. Those inventions challenge the machine designers to select appropriate materials for their design as well as their application.

Neodymium-iron-boron magnets, known as NdFeB, are the most popular and powerful PMs, so they are the most used in electric machines. Since iron and neodymium are relatively abundant, these magnets have similar or lower cost than samarium cobalt magnets. However, the supply situation of both dysprosium and terbium is precarious, as reflected by the market price, which is 9 and 15 times that of neodymium, respectively, since these two rare earth elements are among the most critical elements in terms of supply risk – although some studies reveal that the exhaustion of their reserves is not an imminent concern.

Winding materials offer the potential to significantly lower the cost of an electric machine. Compared to copper one, aluminum windings are cheaper, lighter and more readily recyclable with steel. Since the aluminum has lower conductivity than copper, the challenge for the designers of electric machines will be to come up with a way to achieve the size, weight and power density of machines with copper windings. Using aluclad windings, an alloy of copper and aluminum, could be a hybrid solution that reduces costs but maintains some of the performance characteristics of copper. Alternative higher-performance windings can be achieved through better materials and better winding design to improve fill factor. Other design improvements include using thin multi-stranded wires or laminated windings to reduce the AC winding loss.

Advances in the magnetic and chemical properties of electrical steels can reduce eddy and hysteresis losses, improving overall machine efficiency. Short-term challenges include automotive relevant measurement methods, improved bonding and coating technologies (e.g. self-bonding coatings), achieving lower-loss thinner grade steels and higher alloy content grades for automotive volume.

Challenges faced by electric motors for electric vehicles in terms of topology, control strategies and materials

The propulsion system is the heart of an electric vehicle and the electric motor sits right in the core of the system, thus making the choice of a motor for an electrical vehicle crucial for the design of the whole system. There are numerous types of electric motor topologies and a brief comparative analysis of the main motor categories will be given in this article, discussing how some motor topologies provide the desired parameters for utilizing it into electric vehicle.

Brushed DC motors

Brushed DC electric motors for electric vehicles can achieve some of the requirements for EV applications such as providing maximum torque in low speed, but lack in efficiency and reliability because of the brushes present in them that make heat generation and additional maintenance that makes them less attractive.

The main advantages of these type of motors are their low cost, well established technology, simple yet robust control and reliability. These motors were earlier preferred for use as traction motors but due to the advancement in power electronics there has been a shift towards the AC motors, namely induction and synchronous motors.

Permanent magnet Brushless DC motor

The rotor of this motor is made of PM and there is no winding in the rotor, meaning there is no rotor copper losses, thus making it more efficient than induction motors. The BLDC motor is lighter, smaller, more reliable and better at dissipating heat as heat is generated in the stator.

On the opposite side, this motor has restrained field – weakening ability thus making constant power range quite short. Because of the back EMF generated in the stator windings with increased speed the torque decreases. A field of possible further development is in adding additional field windings which will enhance speed range and will increase overall efficiency.

Induction motor

Squirrel cage induction motors are widely accepted as one of the most suitable motors for electric vehicles. EV The induction motors used in EV are converted/inverter driven for variable speed operation. In such type of applications the induction motors are operated with variable voltage variable frequency supply, so the design for EV is different from the convention design. The IM should have higher efficiency, starting torque, breakdown torque and PWR. All of the stated parameters cannot be achieved at the same time. If one performance improves, other one degrades, so to achieve satisfactory performance a trade-of has to be made between the different performances of the induction motors.

One of the well – known methods used to increase the efficiency of the induction motors, cost effectively is by increasing the stack length. Mainly, the evolution of the power electronics and control systems made the induction and permanent magnet types the most favored ones.

Permanent Magnet Synchronous Motors

Permanent magnet motors are motors where the excitation winding is replaced by permanent magnets. This means that permanent magnet motors have negligible rotor losses leading to an increase in efficiency, but also a decrease in the motor’s operating temperature. Temperature is the limiting factor when it comes to the machine’s maximum power output. This means that permanent magnet machines have outstanding power-to-weight ratios.

The stator magnetic circuits as well as the stator windings of asynchronous and synchronous machines are the same. In both cases, a three-phase system of alternating currents on the stator creates the rotating magnetic field whose speed is determined by the frequency of the network. Synchronous and asynchronous machines differ in terms of rotor construction. The rotor of the synchronous machine has permanent magnets which creates the rotor flux.

There are different rotor configurations of permanent magnet motors. Depending on the location of the magnets on the rotor, common permanent magnet synchronous motors can be divided into two types:

- surface mounted permanent magnet motors which have permanent magnets placed directly opposite the air gap and stator winding

- interior permanent magnet motors where the permanent magnets are hidden inside the rotor.

The main advantage of PMSM with rotor with surface mounted magnets is the simple technical procedure for mounting the magnets. The disadvantage is the exposure of the magnet to the demagnetizing field and centrifugal forces.

Motor efficiency is a feature that electrical machine designers are always striving to improve and increase. The main feature of synchronous motors with interior permanent magnets is increased efficiency. For equal engine torque, the increased efficiency is expressed at low speeds when an increased torque is expected from the engine. The increase in efficiency is achieved by reducing losses in copper, that is, by using magnets with desirable characteristics and by achieving greater induction in the air gap, the reluctance moment in the share of the total moment increases.

Synchronous Reluctance Motor

The synchronous reluctance machines are becoming of great interest in the recent years. They represent interesting alternatives to other machine types for electric vehicles for their robust and plain design and for hazard-free operations. The rotor is designed to produce the smallest possible magnetic reluctance (the resistance to the flow of a magnetic field) in one direction and the highest reluctance in the direction perpendicular. VSD steers the stator field so it “rotates” around the motor. The directionally unequal magnetic reluctance properties of the rotor cause the rotor to rotate with the field and at the same frequency.

The SynRM is similar in design to the PMSM, but consists of a salient rotor without magnets. In general, it can be stated that the SynRM have several beneficial properties, some being high efficiency and high torque per ampere capability. The absence of windings in the rotor reduces the overall heat production of the SynRM and PMSM meaning that both are especially suitable for automotive applications from this perspective.

Switched reluctance motors

Since SRMs are PM-free machines, their temperature operation is outstanding. They exhibit high starting torque and low rotor inertia which leads to fast acceleration capability. SRMs have concentrated windings which have good thermal performance and therefore inherent fault tolerant capability. In addition, SRMs are easily cooled since the heat generated by both iron and copper loss is mainly concentrated in the stator. Test results also prove higher power density than IMs. However, SRMs present inherent limitations. To generate sufficient reluctance torque, SRMs must work under deep saturation conditions; therefore the air gap is usually very small and the magnetic properties of the stator and rotor steel laminations are especially important. Since the power flows through the narrow air gap in the radial direction, important radial forces, vibrations and acoustic noise are generated.

Axial flux motors

Axial flux machines are more common in the brushless permanent magnet types of motors. Motors with Axial flux induction could play a role in the electric propulsion as the rare earth magnets limitation. What makes them a serious player in the usage in the electric vehicles is that the axial length of the machine is much shorter compared to radial one, making them a compact solution that many EV manufacturers require. As a result of the compact and lightweight structure where they allow the inner diameter to be much larger than the shaft diameter. Therefore it means that the diameter‐to‐length ratio is high, the axial flux IM can significantly increase the torque density where the length of the machine is a limiting design constraint.

The axial flux induction motor can have better cooling due to a greater diameter‐to‐length ratio. There are two topologies in which the axial flux motors can exist, single sided and double sided. The single sided rotor axial flux motor contains one stator and one rotor, and the stator can be slotted or slot-less. The double sided axial flux motors can have two configurations – one can have one rotor and two stators on each side, and the other one stator in the center and two rotors on two of its sides. As a disadvantage, they have large attraction forces that exist between the stator and the rotor which causes difficulties in manufacturing. The difficulty in maintaining uniform air gap is another challenge for manufacturers and designers to overcome.

Development of electric motors for electric vehicles: conclusions

It is evident that the market of electric vehicles is going to significantly increase in the next years and decades. Many challenges face the design of a suitable electrical motor for electric vehicles, and various approaches such as achieving high power density and efficiency, frequent start/stop and high rate of acceleration/deceleration as parameters will guide the technological development of the motors suitable for this applications.

This article addressed some of the electrical motor designs that fulfill these criteria’s. The latest trend is toward implementing PM synchronous machine with reduced rare-earth permanent magnets, which makes the PMSynRm machines suitable option. In wheel machines expose significant benefits in terms of vehicle design and improving control of the vehicle dynamics. However on the other side the price is increased due to the complexity of the wheel hub assembly and the high unsprung weight stays as a challenges of the designers to overcome. Improvements in the material properties for magnetic and electric design of the motor, and further introducing new processes and materials bay be a path to improvement of the desired electric motor parameters for electric vehicle applications.