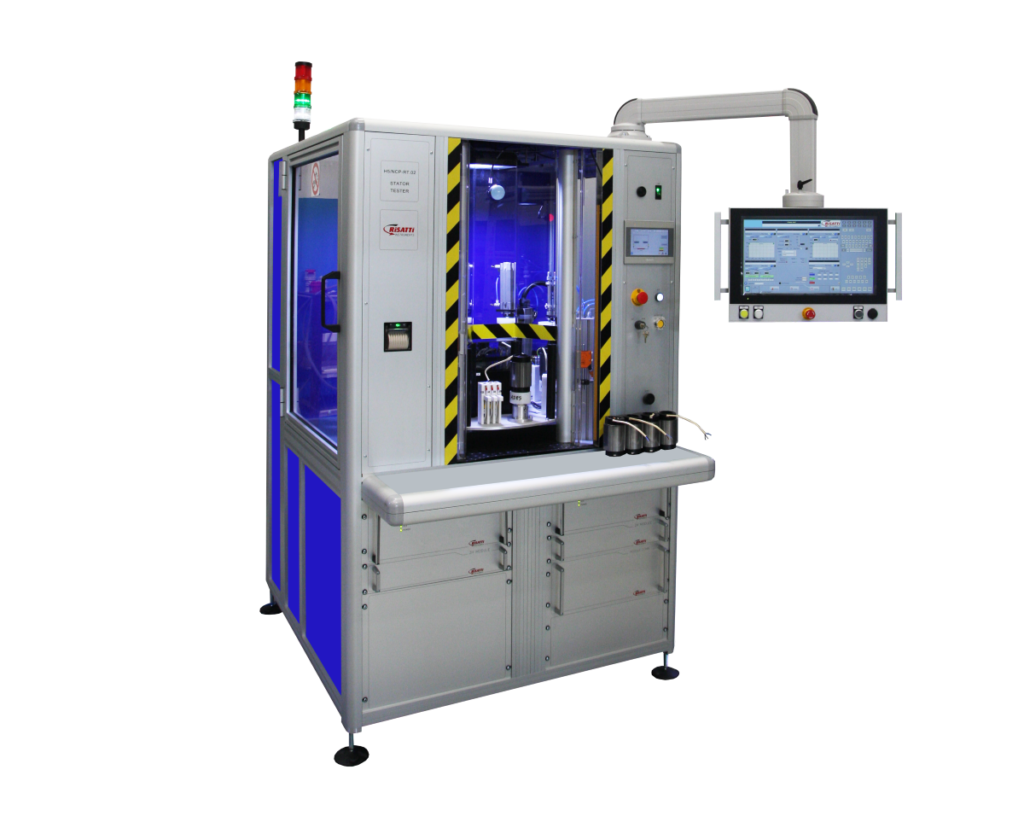

With its consolidated experience, Risatti offers a line of machines for testing windings which represents a definitive and complete solution for:

- laboratory

- repair

- service

- quality control area

- production.

Electrical winding is any circuit wound in coils or turns around the magnetic cores of electrical machines and equipment. Coils are used as circuit components and to provide the magnetic field to motors, transformers, generators, etc. The shape and size of a winding are designed to suit the specifici application.

Parameters such as inductance, Q factor, insulation and the requested magnetic field strength greatly influence the design of the windings.

The main sectors for the application of testing windings relate to: small and large stators, single and three-phase motor stators, continuous stators, coils, alternators, small and medium-sized wound and die-cast rotors and low and medium voltage transformers both connected and disconnected internally.

The measurements are carried out in compliance with Italian CEI, European CENELEC EN, and international IEC standards.

For the appliance manufacturing sector, the winding tests guarantee:

- high performance (also in terms of production volume) in a new interconnected plant setting within the concept of industry 4.0

- integration into production cycles (also with the possibility of automatic loading and unloading using robotized axes and robots) and into company networks with latest generation evolved reporting databases

- extreme standardization of components with contained costs

The line is also made “to measure”, thus enabling perfect customization of the tool.